Download as pdf

Client Background

Terumo Yamaguchi Corporation, a subsidiary of the global healthcare leader Terumo Corporation, manufactures high-quality medical devices and pharmaceutical products. Their production process requires the use of ethylene oxide (EtO) for sterilisation — a highly effective but hazardous compound that demands strict emission control.

Project Objective

To design and implement an advanced emission abatement system capable of treating two very different EtO airflows:

A low-flow, high-concentration stream from the sterilisation chambers

A high-flow, low-concentration stream from the aeration rooms

The solution needed to achieve high removal efficiency, handle fluctuating flows, and be compact enough for international shipment and plug-and-play installation.

Challenges

Treating EtO emissions effectively is always a technical challenge — but in this case, the difficulty was compounded by the dual nature of the emission sources and the international logistics involved.

On the one hand, the scrubber had to manage intermittent, high-concentration gas from sterilisation chambers. On the other, it needed to process a continuous, high-volume airflow from aeration rooms with much lower EtO levels. These dynamic and fluctuating conditions made it crucial to engineer a solution that could perform consistently and within environmental regulations — all while being compact and modular enough to ship from Belgium to Japan.

Key challenges included:

Dual emission sources with drastically different flow and concentration profiles

Meeting strict environmental compliance targets

Managing inconsistent, discontinuous gas flows without compromising performance

Ensuring smooth overseas transport and on-site integration

Trevi’s Solution

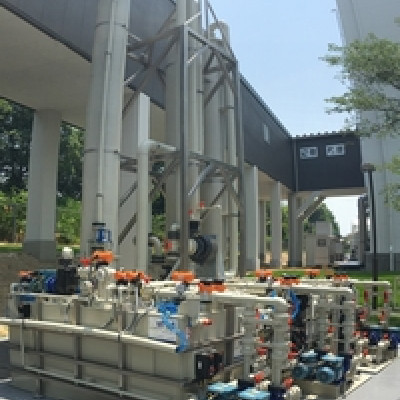

Trevi designed and built a custom three-stage acid wet scrubber, engineered for the complex needs of the Yamaguchi site:

Stage 1: Treats concentrated emissions directly from the sterilisation chambers

Stage 2: Integrates the high-volume air from aeration rooms

Stage 3: Polishes the remaining air to ensure maximum EtO removal

The system was designed for long-term reliability, minimal maintenance, and stable performance under fluctuating conditions.

Results

Achieved 99.66% EtO removal efficiency

Compact system enabled smooth delivery and on-site installation

Fully compliant with Japanese environmental standards

Reliable performance across varying operational conditions

Key Project Specs

Parameter | Value |

Max flow rate | 650 m³/min |

Sterilisation chambers | 50 m³/min @ 747 kg/day EtO |

Aeration rooms | 600 m³/min @ 30 ppmv EtO |

Technology | Acid wet scrubber (3-stage) |

Location | Yamaguchi, Japan |

Completion Year | 2018 |