- → Biofilter

- → Bioscrubber

- → Biotrickling filter

- → Water scrubber

- → Acid scrubber

- → Caustic scrubber

- → Oxidative scrubber

- → Reductive scrubber

- → Solvent scrubber

- → Liquid jet gas ejector scrubber

- → Gas jet liquid ejector scrubber

- → Venturi scrubber

- → Wet dust separator

- → Bubble reactor

- → Dry scrubber

- → Dispersion fan

- → Stripper

Application

Removal of high concentrations of various volatile compounds in gases delivered at overpressure (> 0.1 barg):

epoxides (ethylene oxide, propylene oxide,…)

volatile nitrogen compounds (NH3, amines,…)

volatile sulphur compounds (H2S, mercaptans,...)

…

Principle

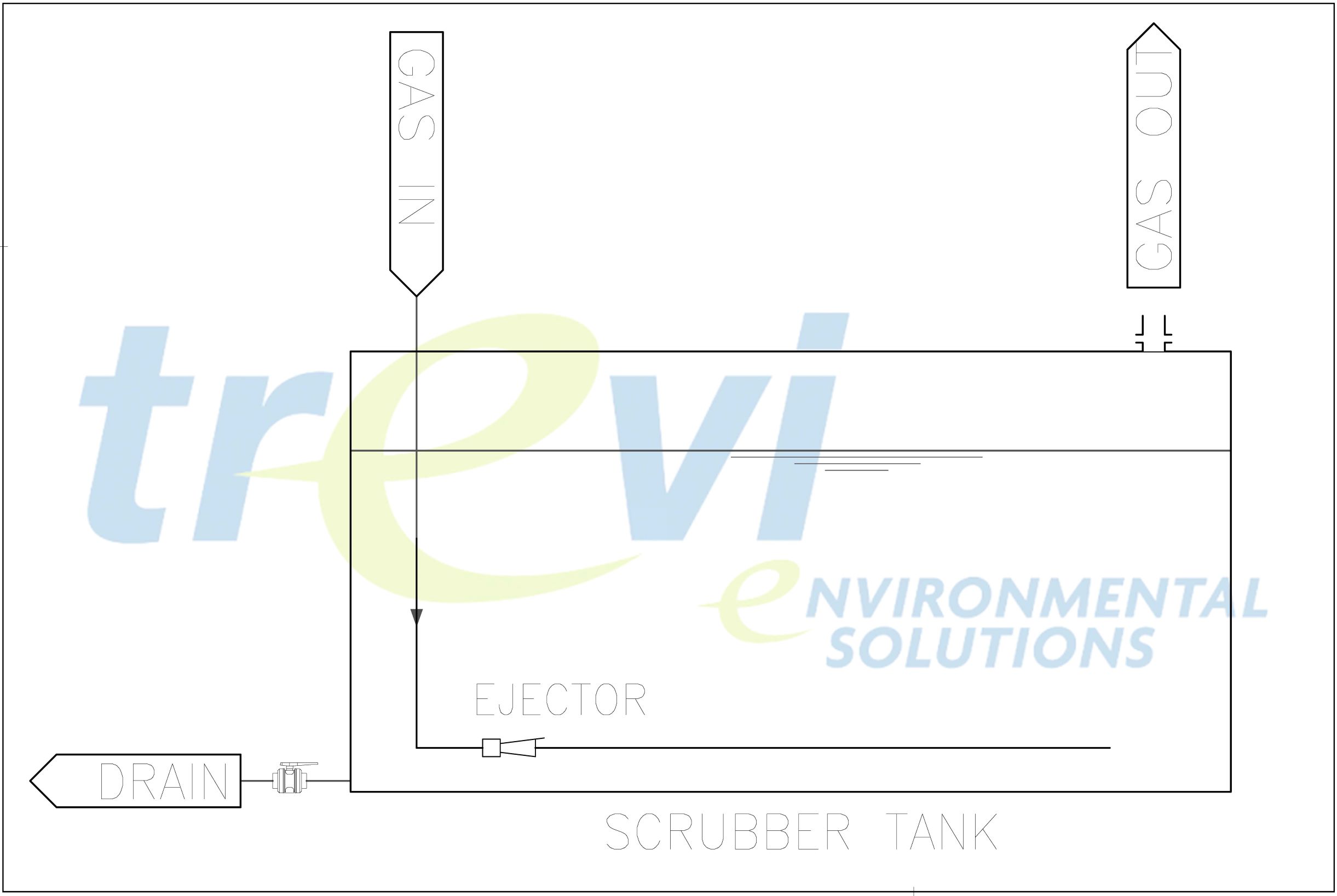

The gas jet liquid ejector scrubber uses the overpressure of the incoming gases to create an intense contact between the gas and the scrubbing liquid in the ejector who is submerged in the scrubbing liquid.

Due to the absence of moving parts (pumps, fans,…), this scrubber technique is a rather cheap solution to obtain very high removal efficiencies upon selecting the suited scrubber liquid.

The scrubber can be operated using various scrubbing liquids. When the correct scrubbing liquid is used, very high (> 99%) removal efficiencies can be obtained. For some applications, a polishing packed bed scrubber is installed after the gas jet liquid ejector scrubber in order to further optimise the removal efficiency.

This type of scrubber is typically used to treat gases upon depressurisation of tanks, railcars, piping couplings etc. The scrubber can also be used as a mobile unit for temporary applications.

Scheme

Realisations

Gas jet liquid ejector scrubber for removal propylene oxide

Mobile gas jet liquid ejector scrubber for removal of ethylene oxide